Chemical Storage Tanks

Chemical Storage Tanks

- Information

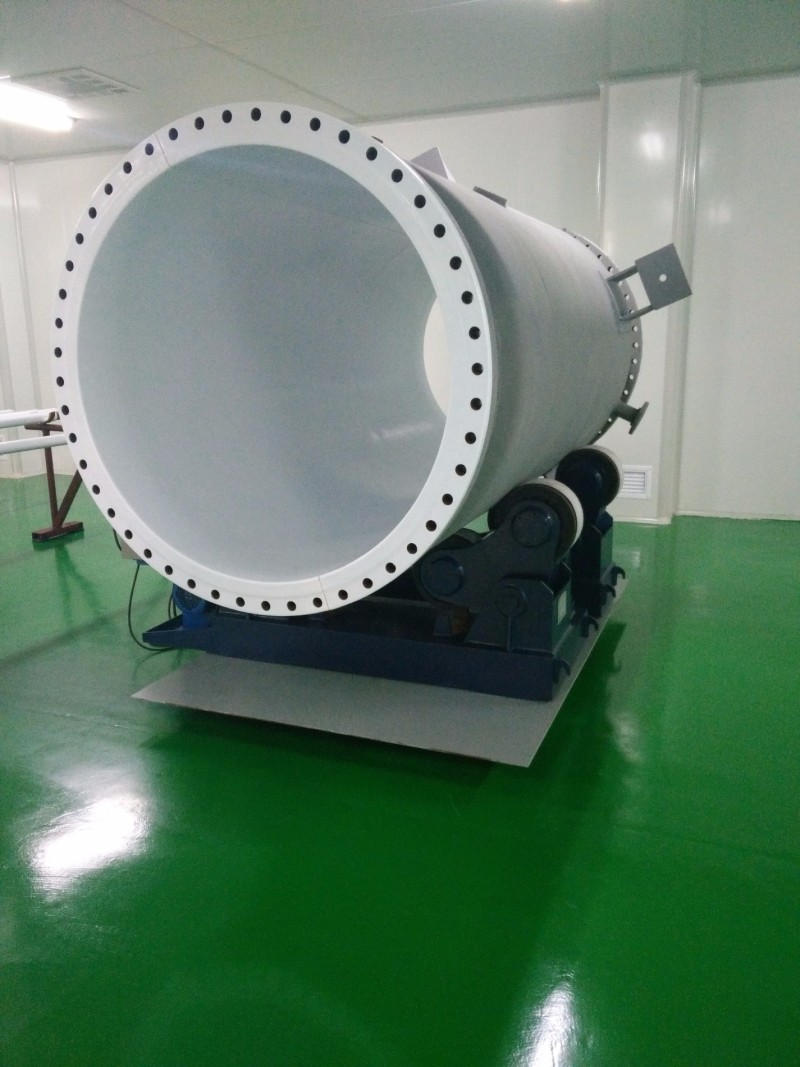

Product description:

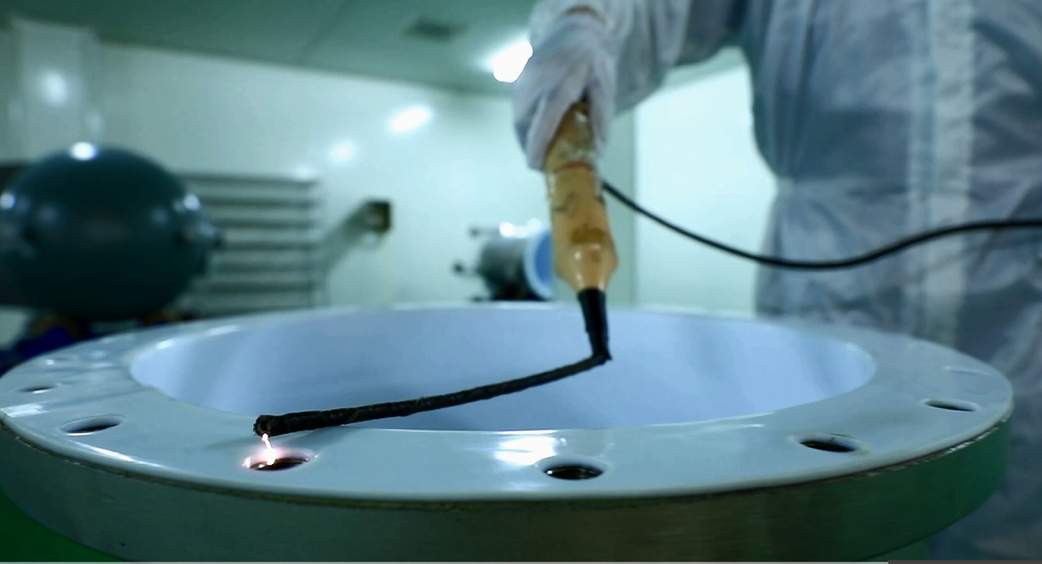

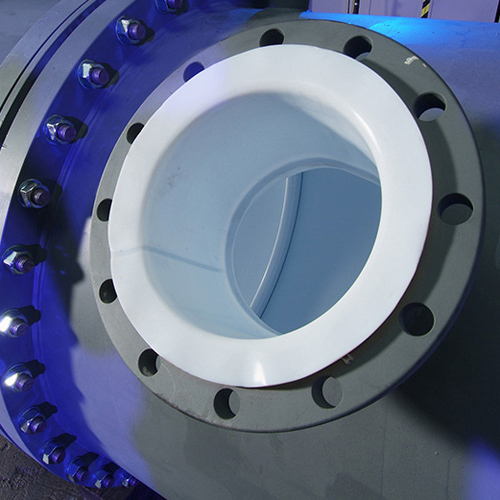

The steel-plastic composite tank is first made of carbon steel tank and then welded with a diamond-shaped steel mesh (100*50*4) on the surface of the barrel. Polyethylene (PE) is used as raw material and rotomolding technology is used. ) The whole body is molded on the inner surface of the steel. Since the steel mesh (turtle net) is integrated with polyethylene and the steel mesh is welded to the surface of the steel body, the polyethylene liner is difficult to separate from the surface of the steel body, and thus is an extremely excellent corrosion-resistant product. The inner lining of the product is smooth, sturdy and sturdy. Compared with the traditional steel lining glass and steel lining rubber, it has good corrosion resistance, wear resistance and long service life.

Product features:

1. Full plastic or steel shell lining plastic (steel-plastic composite) anti-corrosion.

2. The special process is integrally formed in one time, including no seam at the flange, no leakage, and high strength.

3. Good corrosion resistance, a wide range of corrosion resistant media.

4. The material has good toughness, impact resistance and no damage. Compared with ceramics, glass reinforced plastics, and enamel glass products, the impact is easy to break, and the crack is a significant advantage.

5. The material is non-toxic, in line with food hygiene standards, can also be widely used in the production, storage and transportation of chemicals.