PTFE lining plastic tank

PTFE lining plastic tank

- Information

Company to introduce tight liner to absorb foreign technology,high temperature resistance(-40℃~+180℃)negative pressure resistance(less than -0.095mpa),wear resistance and so on .Lining technology not by equipment size of limit,special large equipment cannot transport of can scene construction,lining thickness 2~5mm,lining with plates has PTFE activation Board,PTFE composite glass fiber Board,PVDF composite glass fiber Board,ECTFE composite glass fiber Board.plates of produced has Japan large gold,France three products,Italy GUARNIFLON,China,card and domestic quality plates producer.

"Notes on lining technology"

(1) The lining of steel surface finish:sand blasting cleaning to Sa2 and detergents cleaning impurities,oil and so on.

(2) Imported binders brushing:brushing adhesive lining.

(3) Paste : well plates coated stick to the lining of the surface paste strength>10N/mm.

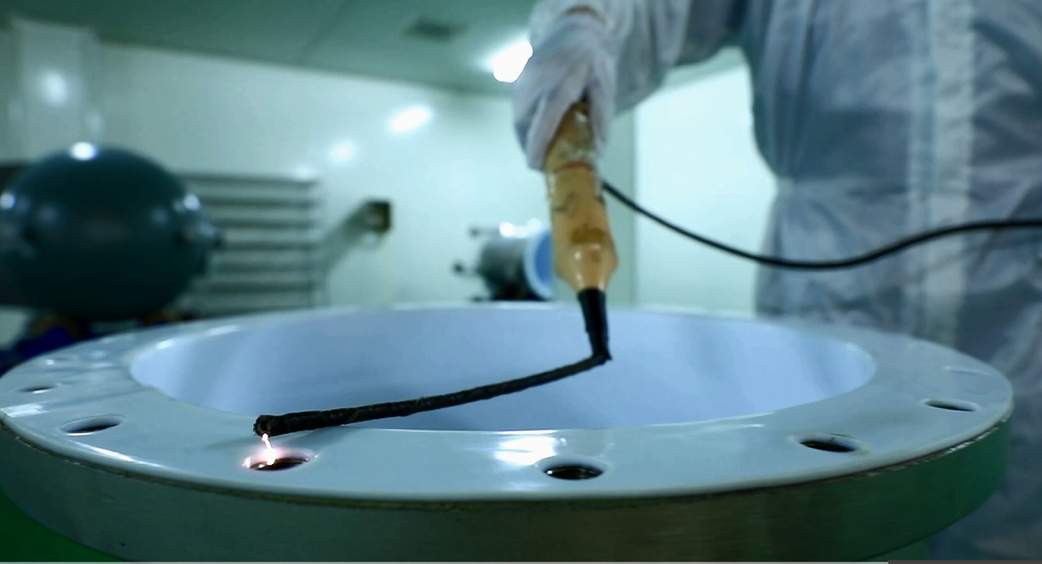

(4) Welding : pasted plate slot welding,weld strength reached more than plate strength of 95%.Spark test voltage 20KV no breakdown.

(5) Nozzle configuration :prefabricated pipe lining into the spout and lined with equipment welding strength reached more than plate strength of 95%.

(6) Spark detection fire 20KV no breakdown.

"Use cases"

Chemical storage tanks,tank,reaction vessel,reaction vessels,the bath of high purity and ultra-pure corrosion of equipment.

In order to make the product both the strength of steel, but also has the corrosion resistance of plastic, I developed a steel-rotten plastic anti-corrosion products. This series of products with lined with a single forming without weld, attached to the solid, the appearance of smooth, smooth wall, no pinholes, no bubbles, impact resistance, high temperature and low temperature, high strength, anti-aging, non-leakage, Acid and alkali, resistant to various solutions, long life, in line with national health standards and the advantages of secondary repair and so on. My company has a plastic, steel-rotten molding equipment, specially suitable for processing all kinds of special-shaped complex, the mouth of a large number of non-standard chemical anti-corrosion equipment.

Selection of materials: According to customer requirements can be used: steel rotomolding polyethylene (PE) products, steel roll rotomol polyolefin (PO) products, and other products.

Scope : Widely used in petroleum, chemical, metallurgy, electronics, pharmaceuticals, dyes, food, pesticides, food, printing and dyeing, electroplating, environmental protection and other fields. In the -80 ℃ ~ 90 ℃ temperature range of the best anti-corrosion materials.

Chemical storage tanks,tank,reaction vessel,reaction vessels,the bath of high purity and ultra-pure corrosion of equipment.