PTFE steel lining stirrer

PTFE steel lining stirrer

- Information

The production steps are briefly described as follows:

In the first step, the agitating paddles that need to be fluorinated are ground, and the corners of the corners are angled to perform a circular arc transition;

In the second step, the PTFE plate is subjected to a special nano-treatment, the main purpose of which is to increase the adhesion of the PTFE plate;

In the third step, the side of the fluorinated PTFE plate and the surface of the agitator are uniformly coated on both sides of the glue;

In the fourth step, the naturally dried PTFE plate is tightly attached to the surface of the agitator by means of high temperature heating;

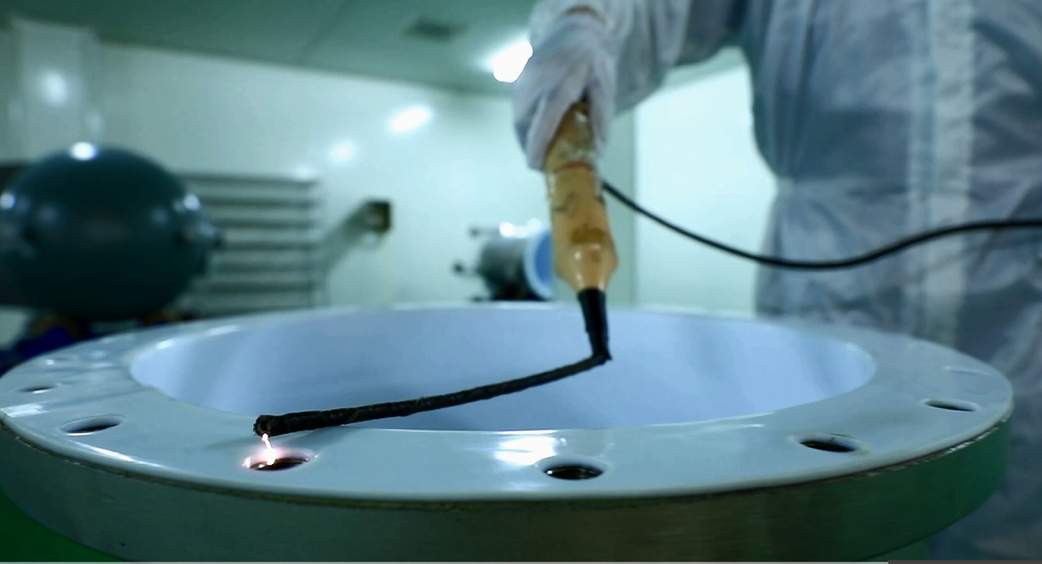

In the fifth step, the corner joint is used, and the PFA electrode is welded by the PTFE welding equipment to perform two weldings;

In the sixth step, the overall anti-corrosion PTFE paddle is subjected to electric spark inspection. If no spark occurs, it is qualified.

Want to know more about the PTFE coating of the outer coating of the agitator, the PTFE price of the outer coating of the agitator, and the PTFE of the outer coating of the agitator, please give e-mail, I believe that your choice will never let you down.