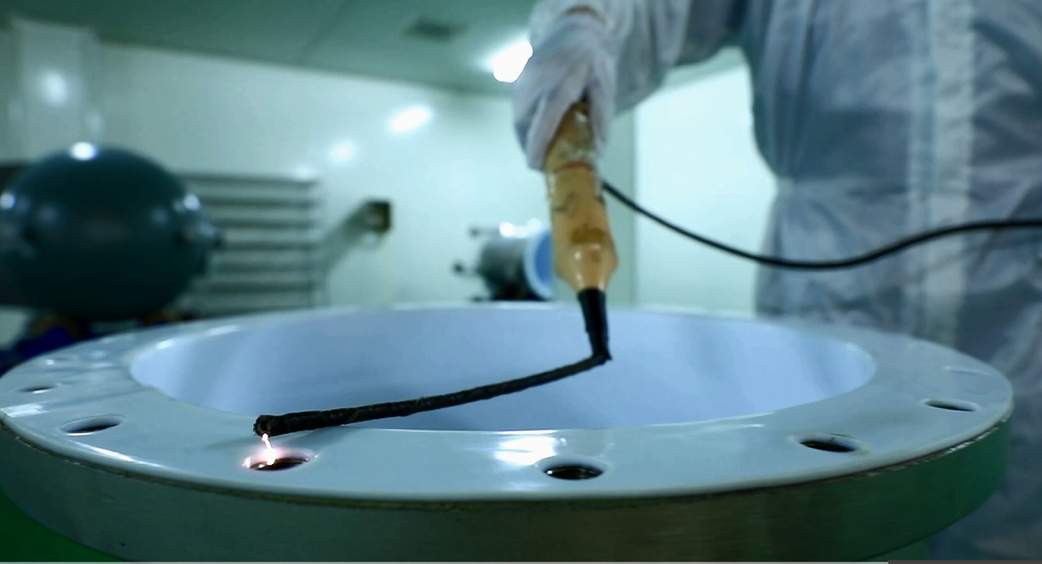

PTFE tight lining custom tower

PTFE tight lining custom tower

- Information

The function of the lining tetrafluoro distillation column is mainly to separate the mixed liquid, and the liquid separation is carried out by using different liquids under different conditions, such as different temperatures and different volatility (boiling point), thereby achieving the purification effect. The lining tetrafluoro distillation tower is mainly divided into a plate tower and a membrane tower. The plate tower is relatively common, and its structure can be divided into three parts: plate, reboiler and condenser.

The temperature at the top of the distillation column should generally be controlled at 79 ° C, the temperature at the bottom of the column should be controlled at 105-107 ° C, and the temperature in the column should be between 88 and 92 ° C under normal conditions. The 1* condenser water temperature on the distillation column should be 60-65 ° C, the 2* condenser should be 35-40 ° C, and the last condenser temperature should preferably be no lower than 25 ° C.

Application of lining tetrafluoro distillation tower in alcohol extraction

In the mature fermented mash, not only alcohol, but also other dozens of ingredients, if added with water, the content of these substances far exceeds the content of alcohol, the mature awake alcohol content is only 7-11% (capacity) ), and the impurities including water, alcohols, aldehydes, acids, and lipids account for almost 90%. To get pure alcohol, a certain method must be used to separate the alcohol from the mature mash. In the production, the method of heating distillation is adopted to separate various boiling points, specific gravity and volatile substances from different equipments, thereby obtaining higher purity alcohol.