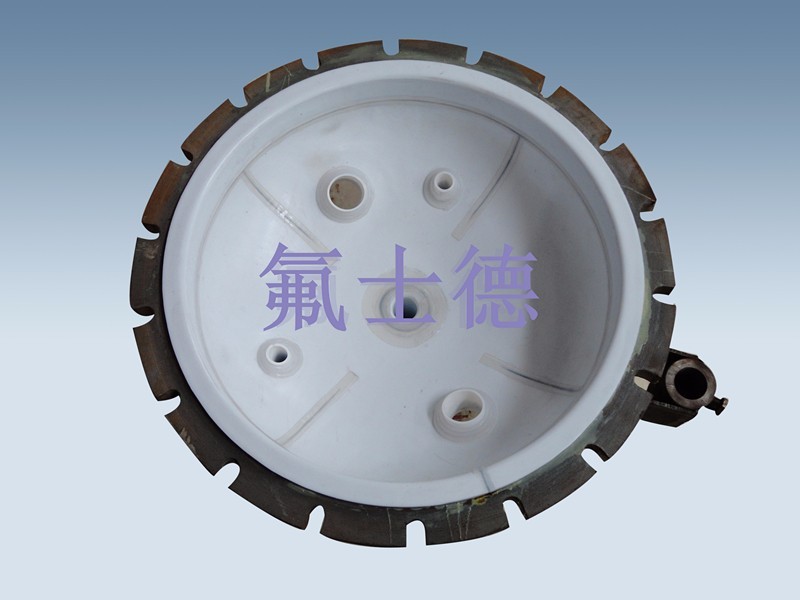

PTFE spray tight lining reactor

PTFE spray tight lining reactor

- Information

PTFE lining is a PTFE lining and polytetrafluoroethylene sheet (PTFE) using hydraulic technology, isobaric molding process, hot-pressure welding process, bonding process and other special processing methods evenly lining the metal container product variety and Uses: PTFE lining products include: PTFE reactor, tank, tank, pump, valve, straight pipe, elbow, tee, cross, compensator, bellows and so on. Teflon lining products are widely used in chemical anti-corrosion fields such as strong acid, alkali, high temperature, high pressure and negative pressure.

PTFE-coated reactor

Scope of application of PTFE: All kinds of strong acid and alkali, the heating temperature outside the kettle should not exceed 180 °C, and the operating temperature in the kettle is ≤180 °C. The heating rate is slow. The temperature inside the kettle can be gradually controlled by the PID temperature control system to control the temperature outside the kettle. Because the stainless steel body and the temperature protection tube are lined with PTFE, so pay special attention to the temperature difference between the heating temperature of the heating furnace outside the furnace and the temperature inside the kettle. The external temperature is too high, which may cause the PTFE liner. Melt deformation. The reactor containing PTFE lining shall not be used for vacuuming. After the reaction is completed, the temperature may be lowered and the pressure may disappear. The cover may be opened and reclaimed. The valve may not be used for venting and cooling to avoid the use of the PTFE sleeve. Pressure: -0.09-+ 1.6MPa Operating temperature: -100 to +200 Lining thickness 2--6mm

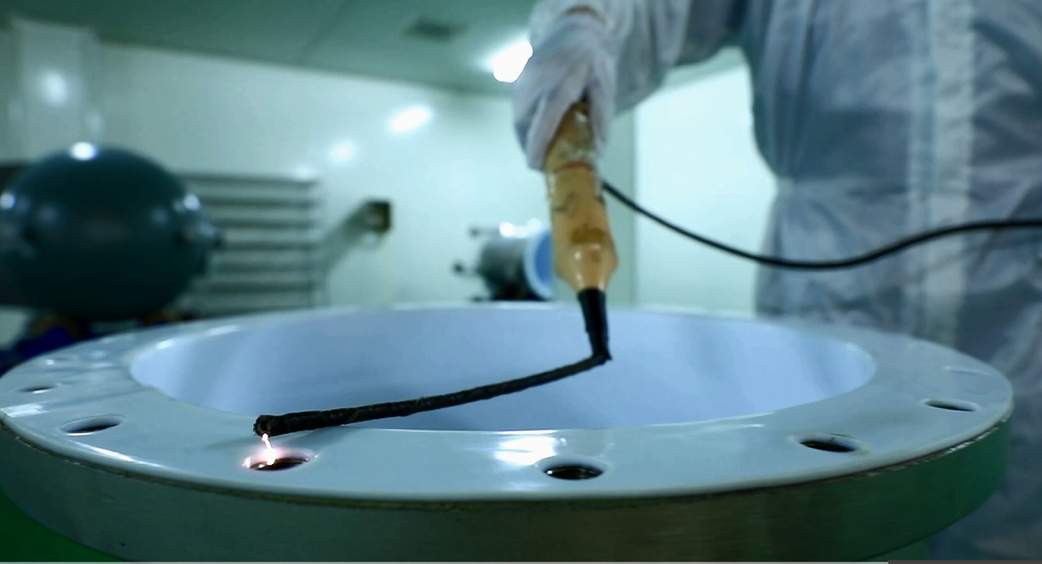

Working principle of lining PTFE reactor

Utilizing the superior physical and chemical properties of various products of PTFE to achieve the desired anti-corrosion effect.