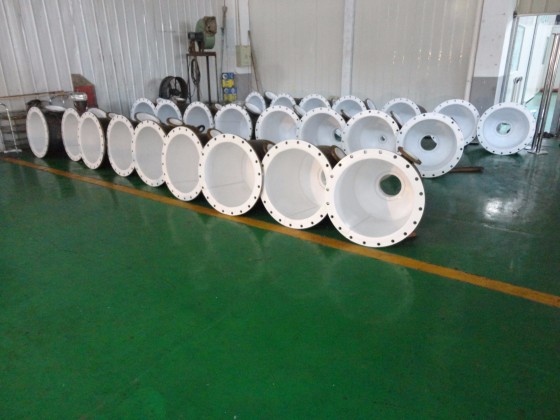

PTFE lining custom tower

PTFE lining custom tower

- Information

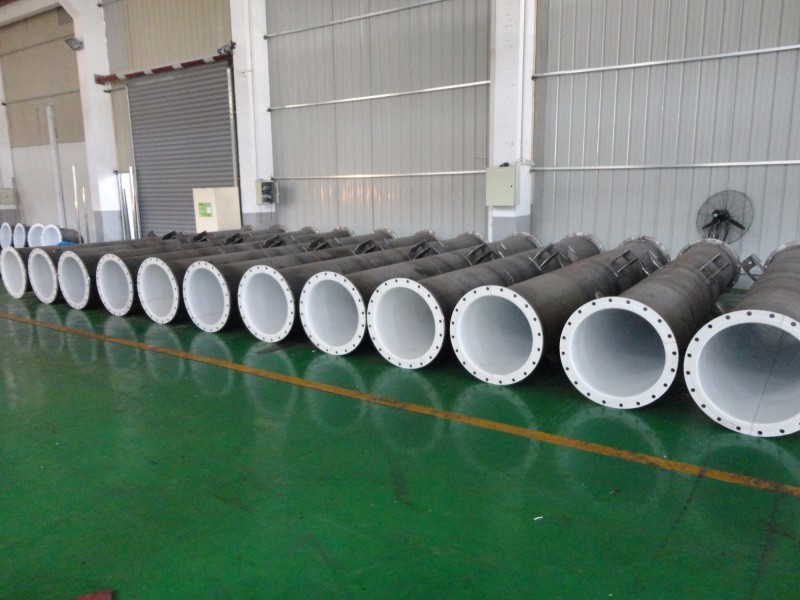

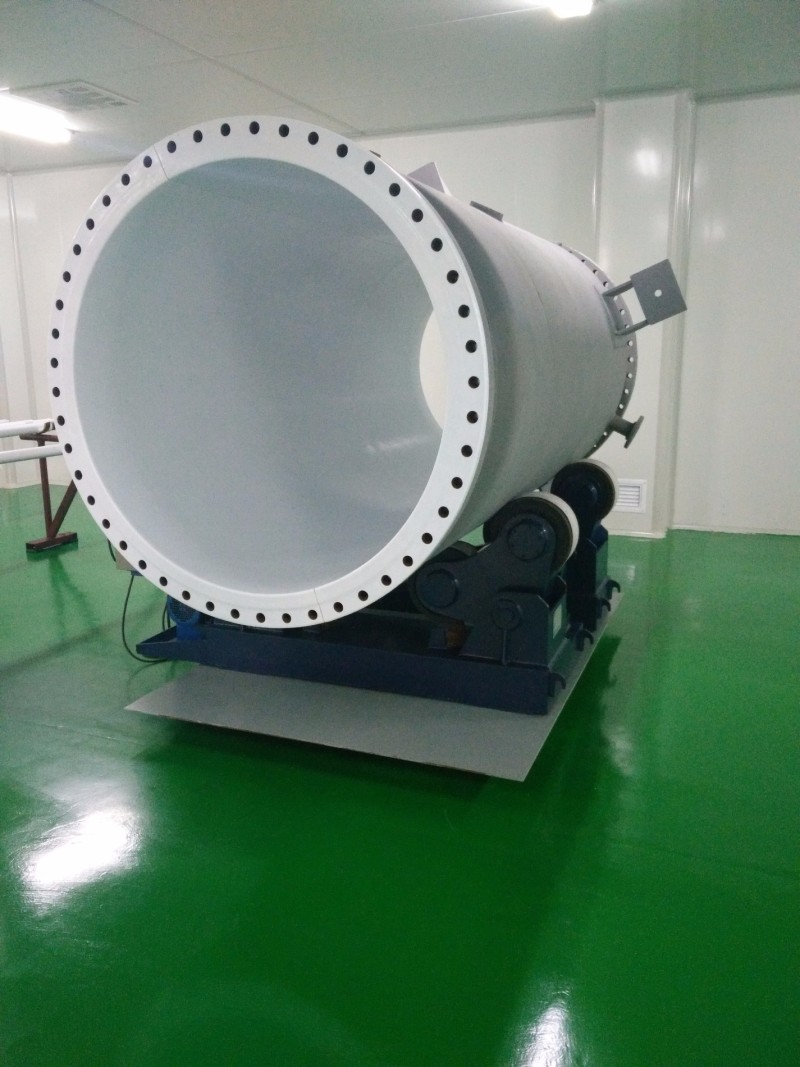

The fluororesin electrostatic spraying process used in spraying the fluorine-containing tower is the advanced anti-corrosion technology in the world. Firstly, the surface of the equipment is degreased and derusted by high temperature, then the surface of the equipment is sandblasted and roughened, and a special primer is sprayed. Then, the fluorine material powder is charged by the high-voltage electrostatic device, and uniformly adsorbed on the surface of the processed device by the electric field, and then baked at a high temperature, the clinker particles will melt into a dense protective layer and firmly adhered thereto. The surface of the workpiece, for example, a 1 mm thick coating film, also needs to be repeatedly sprayed and baked 5-6 times. Generally, the thickness can be sprayed to 2 mm, and the fluorine material is PTFE, PFA, FEP, ETFE, ECTFE, PVDF. Fluoride-coated equipment has been widely used in the chemical industry, pulp and paper industry, food industry and semiconductor industry.

1. The casing of the fluorine-containing tower section conforms to the specification of "steel welded atmospheric pressure vessel" JB/T4735-1997 or "steel pressure vessel" GB150-1998.

2. A variety of lining fluorine material selection: PTFE, PFA, FEP, ETFE, ECTFE, PVDF.

3. Can withstand strong acid and alkali, PH can reach 1-14.

4. The coating and the metal have a very high binding force: the external force can not be removed, the adhesion of the metal and the coating, like the human skin and adhesion. Therefore, it is easy to start the drum between the PTFE layer and the metal base layer of the traditional lining PTFE process. Defects that fall off are more pronounced in environments with frequent temperature changes.

5. High purity, very low precipitation rate, in line with the purity requirements of the photovoltaic industry.

6. The use of a wide temperature, temperature resistance -193 ~ 260 ° C.

7. Excellent anti-sticking performance: It not only has excellent anti-sticking performance after spraying, but also has unique anti-sticking performance in high temperature use.

8. Excellent vacuum resistance: no delamination (withstand negative pressure -0.1Mpa) under any vacuum conditions.

9. Excellent mechanical properties: high mechanical strength and high hardness and toughness.

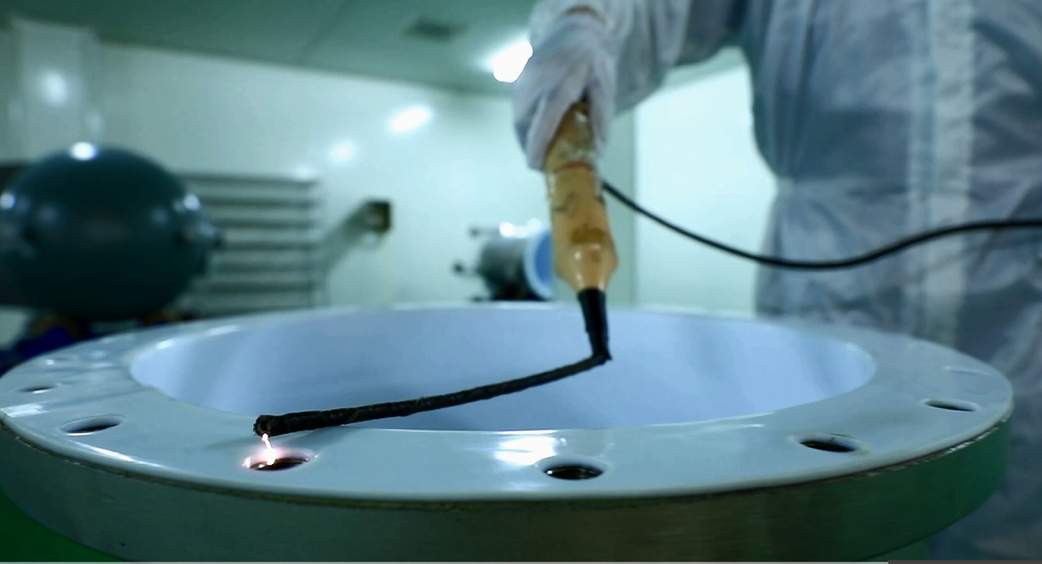

Brief description of spraying PTFE process:

1. Fluorine surface treatment of steel shell lining: cleaning impurities with detergent, removing oil stains at high temperature, and sandblasting and rusting to Sa2 level.

2. Electrostatic spraying of fluorine material: first spray a special primer on the surface of the equipment, then charge the fluorine material powder through high-voltage electrostatic equipment, and uniformly adsorb it on the surface of the processed equipment under the action of electric field, and then dry it at high temperature. Baked, fluorine material powder particles will melt into a dense protective layer firmly attached to the surface of the device.

3. Repeated spraying and baking: Spray and bake the surface of the equipment several times to make the coating film reach the required thickness.

4. EDM detection: EDM is performed on the manufactured equipment, and the spark detection voltage is 20KV without breakdown.

Application areas:

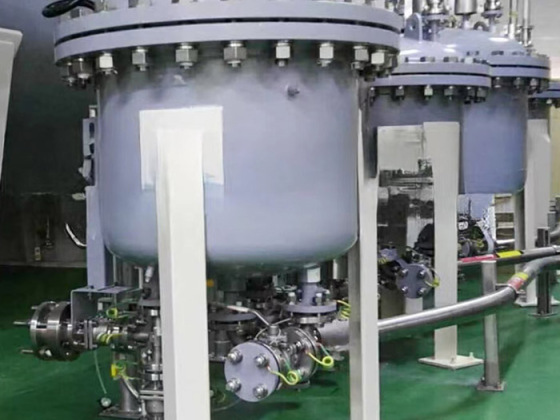

Chemical industry : chlorination reaction tank, sulphate storage tank, sodium hypochlorite storage tank, sulfuric acid storage tank, rinsing lye storage tank, phosphoric acid storage tank, caustic soda buffer tank.

Semiconductor industry : water treatment stations and storage tanks, deionized water storage tanks, high purity acid storage tanks, ultra-pure water storage tanks.

Pharmaceutical industry : pure water storage tanks, salt solution storage tanks.

Power industry : high concentration sulfuric acid storage tank.

Transportation : Land transport chemical storage tanks, barge water transport chemical storage tanks.

New energy industry : ultra-pure water storage tanks for polysilicon projects.