PTFE lining high voltage tower

PTFE lining high voltage tower

- Information

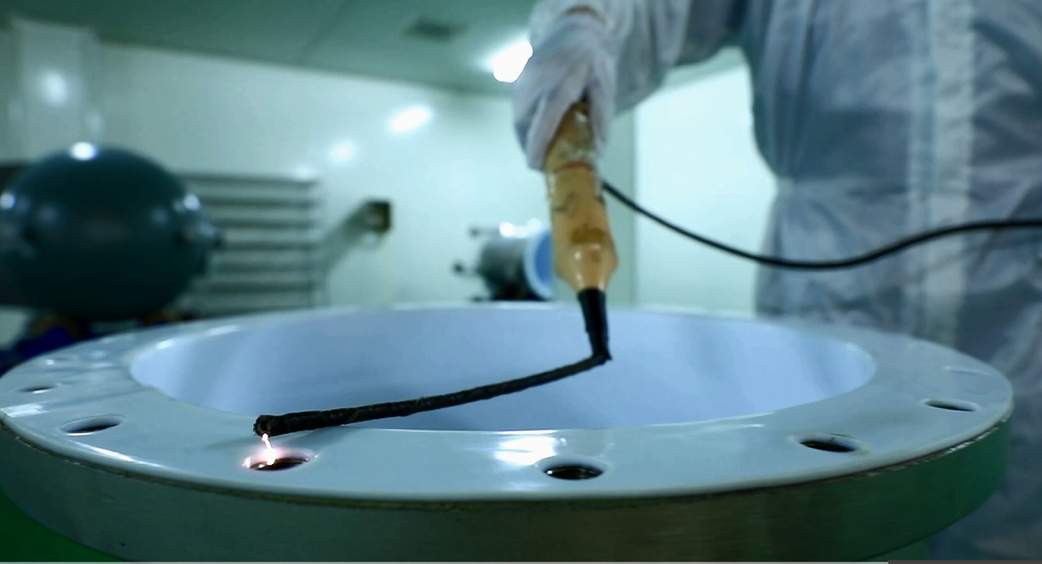

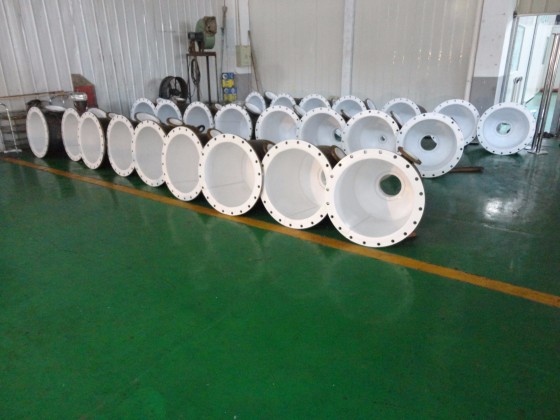

There are two kinds of processes for PTFE anti-corrosion in the tower section. The first one is: adopting the negative pressure-resistant lining process, the long-term use temperature is within 130 °C, the vacuum resistance is 0.09Mpa, and the lining thickness is 4mm. Large-sized towers can be lined up to a diameter of DN4000mm* and a length of 6000mm. The second type is: PTFE spraying process, the long-term use temperature is -160 ° C to 240 ° C. The vacuum resistance is 0.098Mpa. Spray thickness from 1mm to 1.5mm.

There are two kinds of processes for PTFE anti-corrosion inside the tower. The first one is: pure PTFE processing, and then the threads are connected. For example, the filter plate, the peak distributor, the acid separator, and the tweezers plate can be made by this process. Features: The long-term use temperature is within 150 °C. Because the temperature is too high, there will be insufficient deformation strength. The second type is: PTFE spraying process: electrostatic powder coating, (metal surface grinding arc, sandblasting roughening, spray primer, spray topcoat), features: long-term use temperature is less than 250 °C. And there is also the strength of the metal.